Ever heard of a ? It is an essential tool for any person that is drilling. The process of creating a hole in the ground or in hard substance such as rock is called drilling. A button bit makes the job easier and faster. So, let's get to know this unique tool better, its working, and the significance of it for your drilling projects.

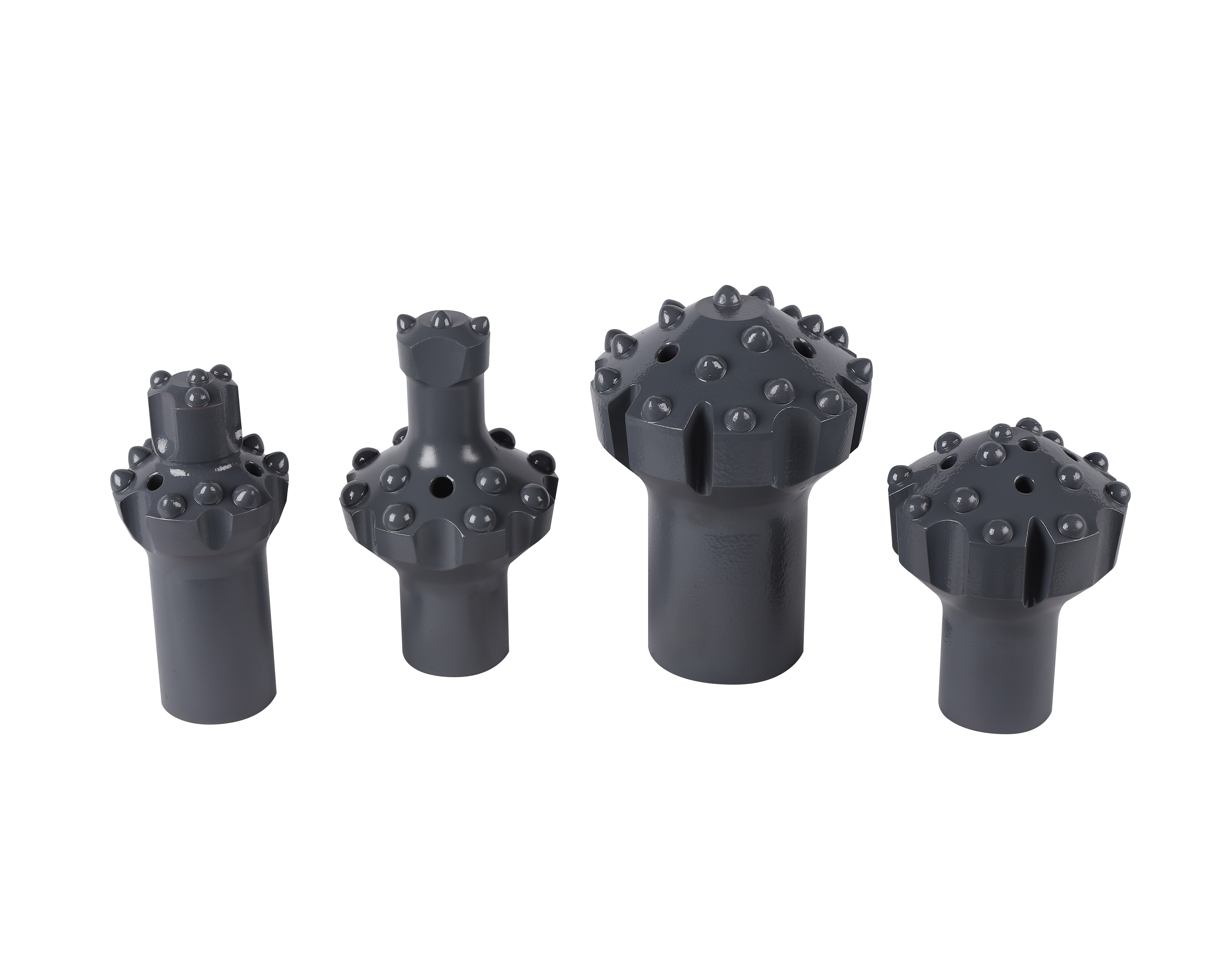

A button bit is a small drill bit that penetrates the earth or rock with great efficiency. It has multiple components that all work together to accomplish the task. The three main elements of a button bit are the bit body, the bit face, and the buttons. These buttons are quite special, are made out of a super dense material called tungsten carbide. This stuff is pretty strong and resilient, even when something is pressing a lot against it.

A button bit is attached to a drill rod. The drill rod is a long, cylindrical metal piece connected to a drill rig. The drill rig is the apparatus used to rotate the drill bit and push it into the ground. As the bit turns and penetrates the earth or rock, the buttons on the front of the bit are put to work breaking up the material. This leaves an empty hole below, which is the goal of our drilling.

But as with anything, there are some disadvantages to button bits. The main drawback is that they can be considered more expensive than other kinds of drill bits. They last, but the upfront cost can be high. The reason be buttons are very hard and therefore they tend to cause wear on the drill rig and other tools as well. That means you might have to replace those tools sooner rather than later.

The size and shape of the buttons on the face of the bit is another key consideration that influences the effectiveness of the bit in drilling. These are made in varying shapes and sizes as well that yield alternative performance and sturdiness. So, selecting the correct buttons will ensure that you achieve the best performance in your drilling operations.

Diamond Button Bits One of the most exciting advances in button bit technology is the development of diamond bits. This new drill is composed of these bits, with diamond-tipped buttons that far exceed the durability of tungsten carbide buttons typically used. That makes them perfect for drilling into very hard rock or other difficult material.

A further development of brilliant button bit technology is the use of computer modeling and simulation. Simply put, this new technology will enable engineers to design and then test new button bit designs before they’re actually made. This allows them to simulate how the bits are going to operate, ensuring that the latest designs are maximum performance and efficiency.