Drill bit regrinding is widely implemented in large mines in developed countries, and many mines in other countries have also tried it with good results, but it hasn't become a habit.

Drill bits are inherently low-value consumables, and the price of carbide components determines the price trend of drill bits. There are numerous drill bit manufacturers, and their product design and production philosophy is geared towards "single-use." On top of this already low-value goal, they compete on price to capture the market, resulting in most drill bits lacking regrinding or reuse value.

Kaiqiu Drilling Tools Co., Ltd. produces drill bits with carbide lengths that support regrinding, and they continue to perform well after regrinding, offering high cost-effectiveness.

Many mining companies that use a large number of drill bits lack environmental awareness regarding drill bit materials and have a weak understanding of drill bit consumption costs. Furthermore, the responsibilities for drill bit regrinding within these companies are cumbersome and unclear, preventing the widespread adoption of drill bit regrinding in many mining enterprises. The few imported regrinding machines remain idle in the corners of warehouses of several units that had previously considered regrinding drill bits.

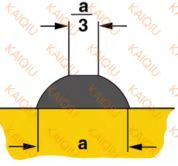

Based on past experience, regrinding is necessary when the step at the top of the alloy post wears down to one-third of the post's diameter. Otherwise, the probability of alloy breakage increases, while also reducing the frequency of alloy post regrinding, increasing regrinding time and grinding cup consumption, and ultimately reducing drilling efficiency.